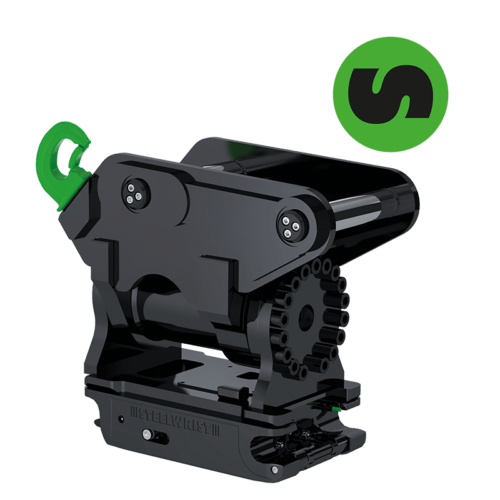

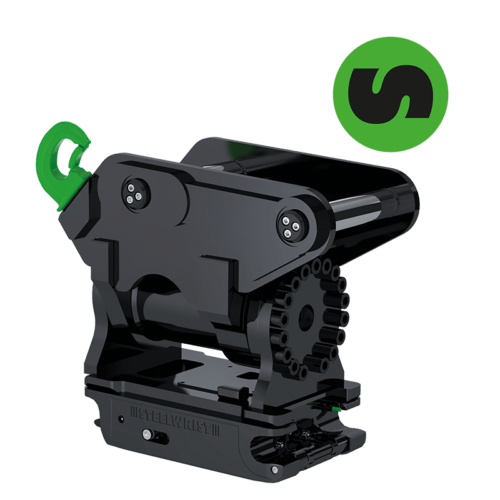

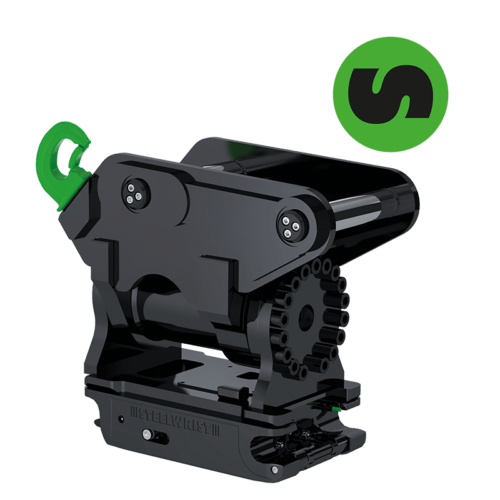

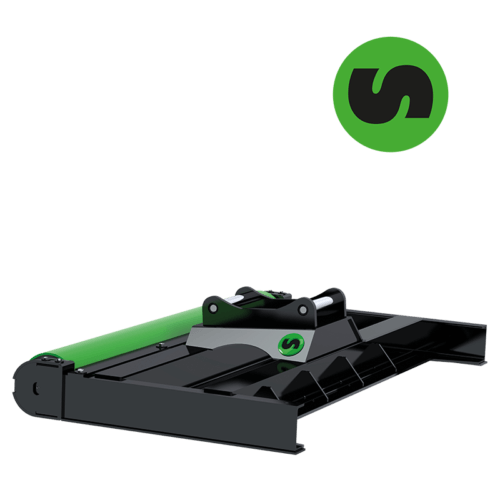

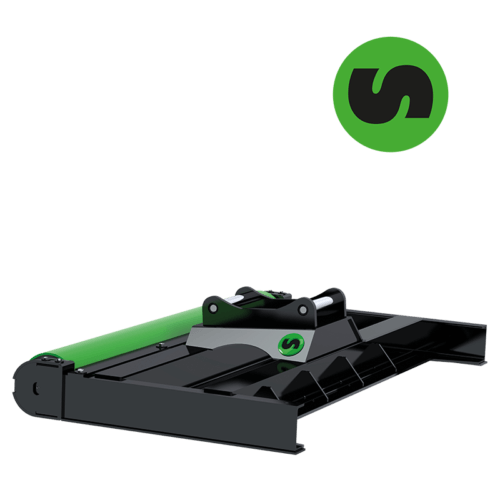

Thanks to a focus on steel molded components, we offer compact tiltrotators with low building height and low weight that gives you optimized digging geometry and the best fuel efficiency.

Steelwrist is the only manufacturer in the market that has a symmetrical coupler completely cast in steel. It’s an extremely robust design free from welding, large pin contact surfaces and material where needed.

Our priority is as always minimum building height as opposed to a simpler manufacturing process. In comparison with other brands the building height can differ as much as 40 percent!

STEELWRIST EARTHMOVING EFFICIENCY BOOKLET